Bigger motors need better protection

John Belshe

Product Marketing Manager

ABB Electrification Products Division

Your large (>400 HP) motors require special protection to ensure reliable operation and a long life. Learn how the features of today’s smarter motor-protecting circuit breakers are up to the task.

If you are driving around town in your personal vehicle, seat belts and airbags provide a reasonable amount of protection. if you’re behind the wheel of 750 HP NASCAR vehicle going 200 mph, the additional protections include a roll cage, helmet, fireproof clothing and more. Greater risk requires greater protection.

The same is true with your electric motors. The small, 60- to 200-amp workhorse motors throughout your facility typically don’t require any protection measures beyond a simple circuit breaker. If one of these motors fails, it can be easily and affordably swapped out, probably with minimal disruption to operations.

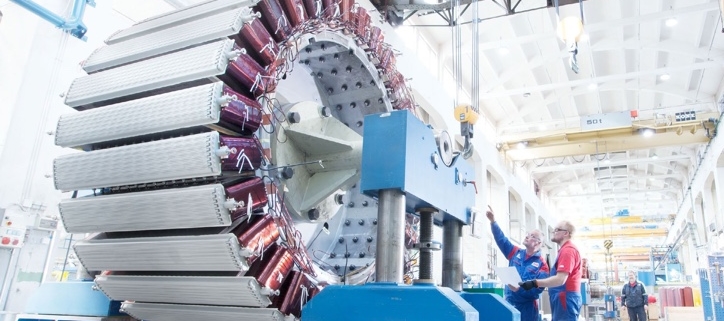

It’s a different story with your large, three-phase asynchronous motors. They tend to be more critical to your operations, and are much more difficult and costly to replace. That’s why these motors usually deserve added levels of protection when starting, switching, and during operation.

Small-motor protection

Most motors in the 60- to 200-amp range are adequately protected with a traditional system that includes a circuit breaker to defend the wiring from damage if there’s a short circuit, and a contactor for motor switching. A thermal relay provides overload protection, primarily from the spike in current required to overcome initial staring torque.

Smaller motors in critical applications or that would be difficult to replace may warrant additional protections. there is a wide range of solutions available to create enhanced protections customized to the application.

With motors in the 200 HP size range and above, it starts to make sense to use motor protecting circuit breakers MPCBs. At 400 amps and above, it’s foolish not to invest in the additional protections and added benefits delivered by digital MPCBs. For panel builders and buyers, there are three primary reason to rely on MPCBs.

1. Reduce panel space and complexity

One of the most important benefits for panel builders is the reduced space requirements. As digital devices, MPCBs are smaller than their analog counterparts. The fact that the breakers eliminate the need for other components like the thermal relay further reduces space needs. Consolidating functions in the breaker also reduces wiring, simplifying panel construction and reducing potential points of failure.

2. Collect application data

The breaker becomes a collection point for a variety of application data that can be shared on a local plant network or via the cloud via a range of communication protocols. Breakers have the capability to accurately measure all primary system operating parameters: current, voltage, energy, power, power factor, etc. A direct connection to the motor temperature sensor (PTC thermistor) adds the ability to also monitor this critical variable.

3. Enable soft trips

The breaker’s ability to interact directly with the contactor can help greatly extend breaker life. Contactors may achieve up to a million operations while the far-more costly breakers, depending on the application and environment, may be rated for thousands of operations. It’s easy to see how relying more on the contactor will save wear and tear on the breaker.

In addition to those broad benefits, MPCBs provide many other advantages that may be of value, depending on the application.

Phase imbalance and undercurrent protection

Undercurrent protection helps avoid damage to the motor if it experiences reduced or null load. More important is the ability to sense and protect the motor from power phase imbalance.

think of the three phases of electric current as a three-cylinder gas motor. a phase imbalance is comparable to having two 1-liter cylinders and one 2-liter cylinder driving the same shaft. the gas motor will literally shake itself the death. the same happens in an electric motor experiencing a phase imbalance. an imbalance of as little as 2% is enough to drastically shorten motor life.

Customized protection

While it’s still necessary to select a breaker with the appropriate size and rating, it’s possible to customize the breaker, tuning it to the application. For example, you can select the desired tripping values, ensuring high trip accuracy and extremely reliable operations.

You can also program how the breaker responds to various application variables, whether that’s an automatic response or summoning help. For example, you can set thresholds for parameters like temperature that will result in a programmed response, whether that’s to trip or open the contactor, or summon help via an annunciator, email or text message.

In particularly challenging applications, where motors have to be replaced every three months, the life-extending features of an MPCB can double that interval.

Rotor blockage protection

The MPCB can detect both jams during operation as well as stalls during startup and take appropriate protective action.

Opting for smarter motor protection

the need for the intelligent, advanced protection provided by MPCBs is amplified when dealing with the high-efficiency motors. They are far more precise, and therefore more sensitive to power issues, especially phase imbalances. They also tend to have longer inrush current. These factors make nuisance tripping far more likely. The power-quality monitoring features and ability to tune the breaker enable MPCBs to overcome these issues.

Motor protection is especially important for motors that are frequently cycled on and off. However, advanced protection is also important in motors that run continuously because power quality can change at a moment’s notice, with the potential to inflict serious motor damage.

In facilities that rely on large motors in vital applications, it makes sense to explore the capabilities of a motor-protecting circuit breaker in the control panel. The expense of the MPCB can often be easily justified when compared to the cost of major failure or shortened motor life.

Recommended Reading: Motor Protection: A solution for any system