Cost-effective short circuit current solutions

With temperatures as high as 35,000 degrees Fahrenheit, an arc flash can result in catastrophic injuries, substantial equipment damage, and unplanned downtime. ABB’s cost-effective short-circuit solutions help utilities and industry increase electrical safety and mitigate the damage caused by an arc flash incident.

In the United States, an estimated 5 to 10 arc flash incidents occur every day, and more than 2,000 people receive medical treatment for burns and other injuries due to these incidents. Furthermore, the economic repercussions of arc flash incidents are profound, with victims often losing six to eight months of work time. These events can also lead to substantial financial liability and property damage, underscoring the dire need for arc-fault mitigation measures.

Arc-resistant switchgear: A critical element of workplace safety

Switchgear plays a pivotal role in both electrical utilities and industrial applications by providing a crucial control mechanism for power distribution. In electrical utilities, switchgear is integral to substation operations, where it is used to both isolate and protect different parts of the power grid. It enables utilities to reroute power, control the flow of electrical power, and protect against overloads and short circuits, thereby ensuring a stable and reliable supply of electricity.

In the industrial sector, switchgear is central to managing electrical power systems within factories, refineries, and other industrial plants. It allows for safe power distribution to machinery, equipment, and lighting systems, supporting operational efficiency and helping to prevent electrical-related incidents. Moreover, switchgear is essential for maintenance and repair processes, as it allows maintenance personnel to easily disconnect equipment and components before servicing.

Because of its foundational role in the distribution and control of power, switchgear is often the source of arc flashes that cause the most damage to people, property, and equipment. These incidents can be attributed to a variety of factors, such as equipment failure, poor maintenance, lack of safety protocols, environmental conditions, and human error.

Arc-resistant switchgear can mitigate the risks to personnel by containing and redirecting the arc energy away from the operator. By confining the arc within the enclosure, arc-resistant switchgear can also prevent the released energy from an arc flash from impacting other nearby equipment and property.

However, as beneficial as arc-resistant switch gear is, it comes with a couple of drawbacks. It requires more space to implement, so it is not always a feasible choice for tight spaces. It is also more expensive than non-arc-resistant switchgear, and therefore, not always budget-friendly. Arc-resistant switchgear is commonly used in new installations and in industries, such as oil and gas, where the arc flash hazards are higher. However, according to ABB estimates, as much as 80% of switchgear installed in the U.S. today may be non-arc resistant.

Advancements in switchgear safety upgrades

Traditionally, upgrading non-arc-resistant switchgear, while possible, was seen as a complex undertaking. Even if these upgrades improved operator safety, they still failed to reach the level of protection required by ANSI C37.20.7. Thanks to innovations from companies like ABB, that is changing.

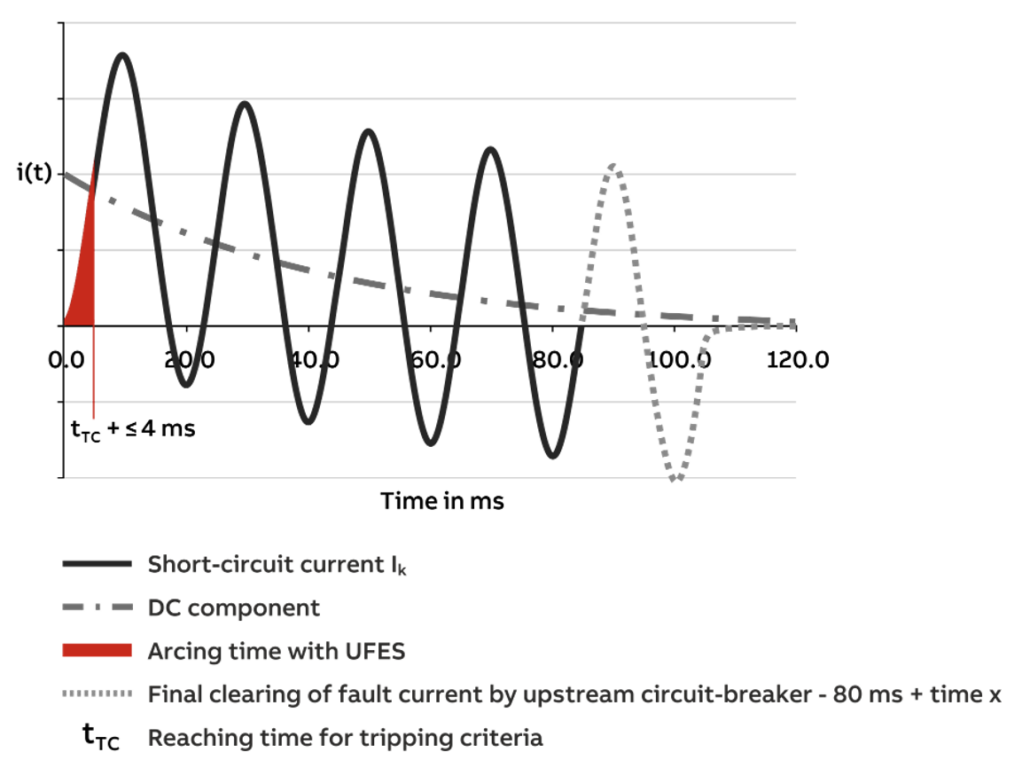

According to ABB engineers, speed is a key requirement in reducing the damage from an arc fault. With a DC superimposed current, as shown in Figure 1, the equipment experiences the maximum load in the first current peak. Current intensity, heat input, and pressure are at their maximum at around 10-12 ms. This is when the greatest damages occur. Traditional extinguishing concepts with a longer reaction time can therefore only prevent a small part of the damage.

Upgrading existing switch gear with components designed to work faster can dramatically lower the damage an arc flash can do. For example, ABB offers the Ultra-Fast Earthing Switch, or UFES, which can detect internal arc faults and swiftly ground the system, effectively extinguishing the arc and minimizing potential damage. This action is facilitated through a combination of current and light sensing and an associated arc-quenching device, known as the primary switching elements (PSE). Upon detection of an internal arc fault, the arc detection relay actuates the UFES PSEs, initiating a three-phase earthing that disrupts the arc voltage and extinguishes the arc, all in less than 4 milliseconds.

UFES is more commonly known in medium-voltage applications, but it is also available as a low-voltage short-circuit solution. Low-voltage switchgear is often installed in urban environments or inside buildings near where people may be walking or working. The danger to people can be greater due to their proximity to the event. In addition, arc flashes can still do considerable damage to equipment and cause downtime headaches for the organization.

Newer to the ANSI market, UFES was introduced in Europe in 2009. To ensure full compliance with the ANSI C37.20.7 standard, an upgrade of non-arc resistance switchgear using UFES would need to be type tested. Once type-testing is completed, the switchgear meets the requirements for arc resistance.

Systems fault mitigation

The UFES protects the system in the event of an internal arc fault and is only applicable in systems where short-circuit current levels are acceptable. A fault current limiter (FCL) however allows systems to operate under conditions that would normally overload the system in case of a short-circuit current. This could, for example, be a spike in short-circuit contribution due to a fault downstream, in which case the current limiter lowers the current to prevent cascade damages.

A challenge frequently encountered by utilities and industry occurs when coupling systems that are incompatibly dimensioned. For example, when two independent electrical systems or networks are connected, they may collectively exceed their short-circuit withstand capabilities. The fault current levels resulting from such a connection can potentially damage system components or lead to operational instability.

In this scenario, one option would be to upgrade the systems to handle the higher fault current, but that can be expensive. A less expensive, faster option is to implement FCLs to manage and limit the fault current levels between systems. This prevents the short-circuit current from reaching levels that could overwhelm the circuit breakers or other protective devices within the network.

Once again, speed provides an advantage. Preventing fault currents from reaching their full magnitude can limit the damage to systems, people, and property. For example, ABB’s IS-limiter is designed to detect and limit the fault current at the first rise, which happens in less than one millisecond. This speed reduces the fault current before it reaches its first peak, providing protection for the electrical network and limiting the mechanical and thermal stresses on the infrastructure.

FCLs are not new. The IS-limiter was first introduced more than six decades ago and has an installed base of more than 10,000 units. This track record of performance is highly critical in applications where process continuity, and therefore power reliability, is essential. By continually improving on the original design, making it faster than any other FCL on the market, ABB ensures the IS-limiter can provide protection for even the most sophisticated of modern systems.

Speed matters for OEMs too

OEM panel builders are tasked with creating solutions for increasingly complex scenarios. ABB solutions provide cost-effective options that promote safety and reliability. Arc-resistant switch gear can be expensive and lead times are long. ABB’s UFES can mitigate the risks of an arc flash incident at a fraction of the cost and time. Likewise, the IS-limiter lets panel builders avoid the need to design systems for double the short-circuit current, thus saving on costs and complexity.

UFES and the IS-limiter are just two solutions in ABB’s product portfolio, which also includes a wide range of electrical components, such as circuit breakers, switches, and enclosures optimized for performance and compliance with international standards. Furthermore, ABB enables panel builders to enhance their operations through digitalization, with tools and connectivity solutions that streamline production and maintenance processes. By offering access to its global network of experts and advanced technologies, ABB assists panel builders in achieving operational excellence, ensuring the safety and reliability of their panel solutions, and allowing them to stay competitive in a rapidly evolving market.

See related blog post “3 Approaches to reducing the danger and damage of arc flash“.

—

Alexander Kischinski

Product Manager – Grid Components

Konstantinos Papapaschalis

Product Marketing Manager – Indoor Apparatus

Daniel Essandoh

Product Marketing – MV Indoor Apparatus