Battery energy storage: Ensuring power reliability at net zero

Utilities and grid operators are keenly interested in battery energy storage systems to support the supplementation and eventual replacement by renewables of fossil fuel generation sources. In recent years, the market for battery energy storage systems has grown to include additional applications such as industrial power backup systems, support for EV charging, and even residential and commercial applications.

This broad array of battery energy storage applications has led to a wide variety of options, from large, centralized solutions, to decentralized stationary and portable systems, to small-scale units designed for a number of needs. Likewise, the technologies used for energy storage may differ. Lithium-ion is still the most common, but other options include high-energy supercapacitors, lead-acid batteries, high-power flywheels, Compressed Air Energy Storage (CAES), and more.

Despite the variability in function and technologies used to store energy, all battery energy storage systems require support components that perform three critical functions:

- Operators must be able to control the source of energy and direct the flow of power to where and when it is needed.

- System components must protect the battery energy storage from power anomalies, the elements, cyber threats, and more.

- Advanced monitoring systems must provide data to inform decision-making, allowing operators to optimize power usage, lower total costs, and ensure power reliability.

Control: The key to reaching net zero

By controlling the flow of power, utilities, grid managers, and industrial/commercial power managers can integrate renewables to increase the percentage of renewables while controlling costs. Some techniques used include:

Load leveling involves storing power during light demand and delivering it when demand is high, reducing the load on the distribution grid and less economical peak-generating facilities. By smoothing the demand peaks, load leveling helps minimize line losses due to resistance in transmission and distribution lines common during periods of peak demand, thereby improving grid efficiency.

Peak shaving is similar to load leveling but is used to reduce peak demand to lower the cost of operations. Power controllers are often deployed to provide advanced, real-time control over power consumption to help users align usage to contractual agreements. For example, a manufacturer might use battery energy storage systems to store electricity during off-peak hours when it is less expensive and then discharge that energy during peak periods when the cost of power is higher.

Frequency regulation helps prevent disturbances in grid frequency that can impact the quality and reliability of power. Variable by nature, wind and solar can lead to frequent fluctuations in grid frequency, making it more difficult to maintain a stable grid. The load-balancing benefits of battery energy storage can help stabilize grid frequency.

Capacity firming smooths the output and controls the ramp rate (MW/min or kW/min) to eliminate rapid voltage and power swings on the electrical grid. This helps increase grid reliability, improve the efficiency of the renewable plant, and support grid code compliance.

Power quality applications protect downstream loads against short-duration events that affect the quality of power delivered. Energy storage with reactive power capability can provide frequency and voltage support and respond quickly to voltage control signals.

Spinning reserve means the battery energy storage is charged and ready to respond to a power failure. This minimizes the impact of power outages and reduces the need for generation sources to be online and ready to use, lowering operational and maintenance costs as well as emissions.

Protecting people, property, and equipment

With battery energy storage being used in an increasing number and types of applications, system protection is vital. Many protection devices are designed to protect the core of the system, the batteries themselves. Examples include:

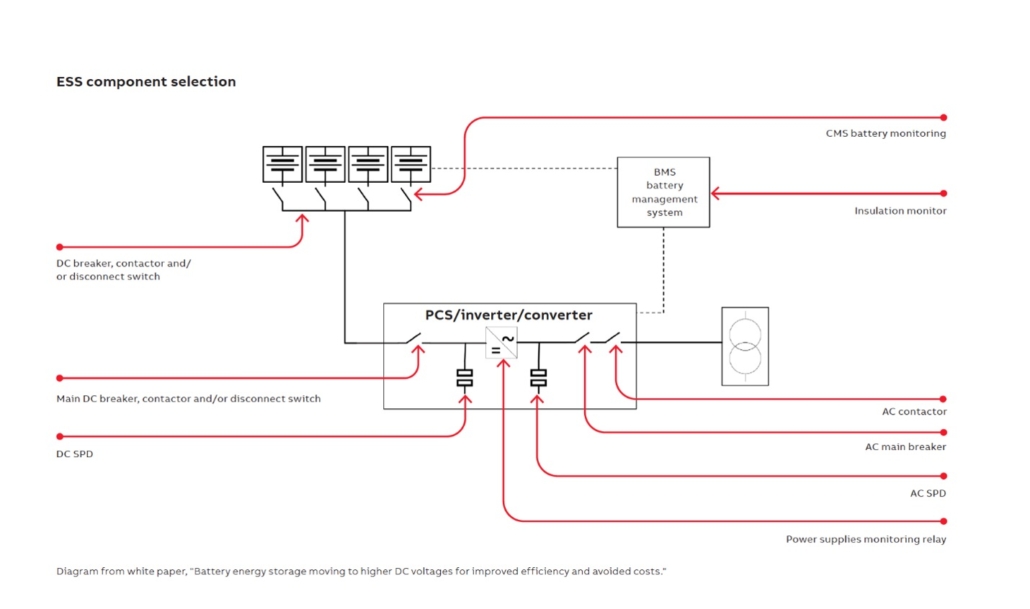

- Battery Management Systems (BMS) manage cell-level conditions, including voltage, current, and temperature. This ensures the battery operates within safe parameters and can isolate faults to prevent propagation.

- Overcharge/over-discharge protection ensures individual battery cells or modules do not exceed their voltage limits during charging or discharging, which can cause damage or reduce lifespan.

- Thermal management controls the temperature of the battery system to prevent overheating or operation outside of temperature specifications. This may include active cooling or heating systems.

- Insulation Monitoring Devices (IMDs) monitor the insulation resistance of an electrical network. By helping to prevent disruptions due to severe secondary insulation faults, they enhance the reliability and efficiency of battery energy storage.

- Contactors are used for connecting or disconnecting different battery modules or strings to optimize the battery’s performance and lifespan and improve equipment safety.

Protection components also include the many devices designed to protect against electrical faults, short circuits, lighting strikes, and other anomalies that could pose safety risks or damage the system. For example:

- Surge protective devices defend against transient surges, such as those from a lightning strike, that can damage or degrade the performance of the battery energy storage system or destabilize the grid. 1500 VDC has become a common requirement in photovoltaic applications, but the interest in higher voltages continues to grow.

- Fuses protect the battery energy storage system and the grid from overcurrent conditions.

- Circuit breakers safeguard the battery system and the grid against damaging overcurrents or short circuits. They also facilitate the charging and discharging of battery energy storage based on demand and generation.

- Transfer switches provide a smooth and swift transition between power sources and help safeguard against power quality issues during the transition process.

As with any electrical application, measures must be taken to protect property and people from the environment, natural disasters, equipment failure, and threats from malicious actors.

- Equipment enclosures provide physical security and environmental protection for the battery modules and associated electronics. These enclosures are often designed to be fire-resistant and to prevent ingress of water and dust.

- Fire detection and suppression systems quickly detect and respond to thermal events or fires within the battery system to mitigate risks to the equipment itself, prevent large-scale damage to surrounding equipment and property, and protect employees and the public.

- Cybersecurity algorithms protect the system from unauthorized access and cyber-attacks, ensuring secure communication and operational integrity.

Intelligent monitoring for a low-carbon grid

Many of the components discussed come with built-in intelligence, enabling the collection of data from the entire network. From monitoring energy consumption to the deployment of energy sources to control of operations and costs, these systems work together to provide operators with the visibility they need to achieve their objectives.

For example, Circuit Monitoring Systems (CMS) can play a key role in the implementation of battery energy storage systems. Advanced CMS allows the operator to identify potential savings related to energy consumption and detect risky situations before they lead to service interruptions or load failures. This helps guarantee uninterrupted power supply and service to customers.

Artificial intelligence and machine learning have also become state-of-the-art for advanced battery energy storage applications. With tools such as ABB’s Ability™ Energy Manager, AI can be used to analyze large volumes of data and forecast periods of high production from renewable resources or anticipate electricity demand spikes, directing the battery energy storage system to store or discharge energy at optimal moments.

AI can also contribute to the longevity of the battery energy storage system, a key factor in achieving a low-carbon future. Predictive maintenance enabled by AI can reduce operational costs and extend the life of batteries, increasing the overall efficiency of the system.

Innovating for the future

As with any innovation, need often drives advancement. The need to safely and reliably integrate renewables into the power grid has led to a wide array of battery energy storage systems for different types and levels of applications. ABB supports these systems with sophisticated, high-quality, reliable components that provide the control, protection, and monitoring capabilities needed for advanced grid and industrial applications.

Until now, integrating renewables has been a matter of supplementing traditional power generation sources. As sources like wind and solar take on a greater share of the load, even more sophisticated systems will undoubtedly will need to be developed. ABB stands ready to support this transition with advanced, future-proof devices that help customers meet their goals today while working toward their long-term vision of a net-zero tomorrow.

See related blog post “Renewable energy storage = Big opportunities for OEMs and panel builders”.

—

Brian Nelson

Renewables Segment Leader

John McHale

ABB AbilityTM -Smart Power

Will Hulbert

Product Marketing Manager

Tanvi Dixit

Product Marketing Manager

Cassidy Cohen

Product Marketing Manager