Choose the right combination motor controller type for your next panel

Combination Motor Controller (CMC) provide the four essential elements of motor branch circuit protection and control. Panel builders should understand the benefits and drawbacks of the five most popular CMC types.

Of all the pieces of equipment in a production or process facility, the electric motor is the most fundamental and is probably the most critical. Nothing gets made or moved without a motor. So, it’s only logical that plant operations personnel must maintain the safety of those motors. Panel builders provide that protection via a number of protection and control systems.

Selecting the optimum system requires consideration of the basic motor operating parameters including horsepower rating; power characteristics such as voltage and available short circuit current; vibration, torque, and other mechanical limits; and others. Within those parameters, panel builders must also choose the desired motor protection scheme.

North American standards require that each motor branch circuit-protective system meets four functional requirements: a disconnect means, short circuit protection, a control means, and overload protection. These functions are often performed via a Combination Motor Controller (CMC) that may consist of individual components or a single device.

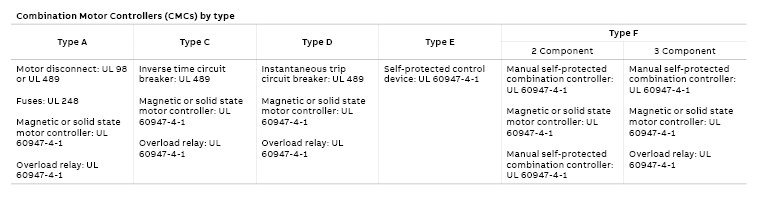

CMCs are classified by type, with each type consisting of different configurations. Understanding the difference between CMC types will enable you to make smarter component selections for motor control panels.

In a CMC the following functional requirements are needed:

- Disconnect means

- Short circuit and ground fault protection

- Control means

- Overload protection

Type A

Type A CMCs are built using separate components for each function. Unlike the other combinations listed in this article, the Type A use a switch disconnector to deliver the disconnect means. This gives the panel designer the greatest ability to customize the protection scheme, whether to meet their production preferences or customers’ requirements. There is a range of suitable components available for each function, with a variety of voltage, short-circuit ratings, and functional parameters.

However, when selecting the desired components, panel builders can use the tested Type A combination suggested by a specific manufacturer. This reduces the number of the tests needed and ensures panel performance.

Within the required specifications, there is matrix of disconnects, fuses, controllers, and overload relays that have been tested in combination within a panel. For most combinations in the UL file, the manufacturer publishes the information in a table/spreadsheet. The tables are available as downloads from the UL website UL Fact Sheet: Short Circuit Current Ratings for Combination Motor Controller Components.

Types C and D

Types C and D are very similar. The major difference between them and Type A is that C and D combine the disconnect and short circuit protection into one device, a circuit breaker, reducing the component count and required panel space.

Fuses provide adequate protection for higher short circuit currents at a lower initial cost than a breaker. The downside of fuses is that restoring service after a fault requires fuse replacement. This always takes longer than resetting a breaker, adding extra costs and system downtime. Some breakers automatically reset, minimizing downtime and reducing the need for maintenance activity.

Comparing Type C to D, Type C relies on inverse time and Type D instantaneous tripping. An instantaneous trip breaker responds faster to faults, increasing the overall breaking capacity of the CMC. On the other hand, an inverse time curve breaker is more flexible in combination with other (upstream) protections, allowing a better isolation of the fault and possibly a less extended downtime.

Type E

Type E is the only CMC that consists of a single component, making it the right choice when panel space is limited. They are well-suited to panels controlling simple motor systems, up to 65 amps and less than 50 hp.

A major difference between Types E and F is the number of expected ON/OFF cycles. Type E controllers are for applications where the motor is cycled infrequently, such as ON at that start of the shift and OFF at the end. Type F, on the other hand, can reliably cycle the motor hundreds of thousands of times.

Both Type E and F rely on manual motor starters. Due to this starter type’s compact nature, Type E and F CMCs are slash voltage rated (e.g. 600Y/347 V AC). This limits their use to solidly grounded networks at higher voltages (e.g. above 347 V AC).

Manual motor starters certified as CMCs have to meet two specific criteria. First, they must have line side terminal spacing of two inches over-surface (creepage) and one inch through air (clearance). Some components are built with that spacing; while with others, the criteria can be met by adding an accessory.

The other criteria have to do with differentiating between thermal (overload) and magnetic (short circuit) trips, which facilitates troubleshooting. In manual motor starters, a smart solution is to use an integrated indicator window that provides feedback on the nature of the power issue.

Type F: 2-component and 3-component

Type F CMCs were introduced in early 2000 to standardize the use of Type E motor protection in combination with contactors. Manufacturers were adding contactors to Type E CMCs, enabling them to provide a far greater number of ON/OFF cycles compared to the Type E. However, the combination wasn’t tested for that purpose, something UL pointed out in a new regulation.

Type F constructions are divided into two styles: 2- and 3-component assemblies. 2-component Type F assemblies use a manual, self-protected device for both short circuit and overload protection while the 3-component version has a separate overload relay.

3-component assemblies provide additional benefits, including selectable Class 10, 20, 30 overload protection (electronic), along with a wiring schematic identical to that of a conventional combination starter (e.g. molded case circuit breaker, contactor, and overload relay).

Smarter CMC selection

Panel builders have tremendous flexibility when it comes to selecting the protection scheme in motor control panels. Even with the limitations of UL tested combinations, there are still many options provided by the various CMC types that enable you to build in the required protection while meeting customer preferences.

—

Francesco Prestinari

Motor Starting and Safety – Area Sales Manager

Keith Sink

OEM Channel & Segment Director

ABB Electrification Business