Energizing uptime: 4 technologies that improve system reliability in warehousing and logistics

In the era of online shopping, uptime is crucial for warehouse and logistics businesses. OEMs need to deliver machinery that is reliable, efficient, and boosts productivity. By leveraging advanced technology, they can keep their customers’ businesses flowing.

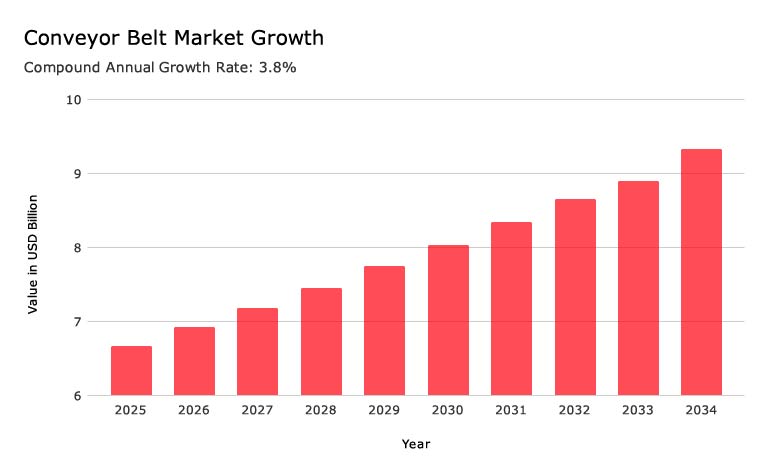

The market for conveyor belt systems in the United States is expected to experience significant expansion over the next decade, driven by the continued increase in online shopping and parallel increase in the scale and complexity of warehouse operations. As businesses strive to keep pace with rising demands, investments in robust conveyor solutions have become essential for efficient product movement. OEMs serving these companies can help them keep revenue flowing by providing comprehensive conveyor belt systems that stand up to the mechanical and electrical stresses of today’s business environment.

Source: Conveyor Belt Market Growth Analysis – Forecast Trends and Outlook (2025-2034)

#1 Monitoring relays

Monitoring relays play a critical role in ensuring uptime by detecting potential power issues that can damage the motors that drive most conveyor belt systems, resulting in costly repairs, operational downtime, and safety hazards.

- Phase monitoring verifies that all phases are present and in the correct sequence.

- Current monitoring adds another layer of protection by detecting abnormal current flows that may indicate overloads, short circuits, or equipment malfunctions.

- Voltage monitoring ensures that the voltage supplied to conveyor motors stays within safe operating limits.

Single-phase monitoring relays are ideal for smaller conveyor systems powered by single-phase AC sources. They protect motors and equipment by detecting issues such as voltage drops, spikes, or loss of power, helping prevent unexpected shutdowns and equipment damage. In contrast, three-phase monitoring relays are vital for industrial setups with three-phase motors. These relays monitor for phase loss, phase sequence errors, and voltage imbalances, all of which can lead to costly motor failures and operational disruptions.

#2 Machine Safety

Every year, an estimated 9,000 workers are injured in conveyor belt accidents in the United States. Depending on the severity of the accident, downtime can last anywhere from a few minutes to days or longer if the incident warrants investigation. Adding a machine safety solution utilizing devices like rope pulls, safety relays, and safety PLCs helps safeguard both man and machine. Not only can machine safety systems help reduce equipment damage and workplace injuries, but these systems are also required by law for many types of hazardous machinery.

Machine safety systems give industrial customers a straightforward yet effective method for quickly stopping dangerous equipment in an emergency. When a rope pull is activated (i.e., the rope is pulled), the safety relay or safety PLC detects this and sends a stop signal to any hazardous movement (e.g., the conveyor system). While stopping equipment quickly can increase wear and tear, this is necessary to prevent/mitigate personnel injury or machinery damage.

#3 Soft starters

Soft starters are electrical devices used to start and stop the motors that drive the conveyor belt. Their primary function is to control the initial inrush of current when an electric motor starts, reducing mechanical and electrical stress. This is achieved by gradually increasing the voltage supplied to the motor, allowing it to ramp up to full speed smoothly rather than starting abruptly.

For conveyors moving larger, heavier boxes, soft starters are commonly used. In addition to the benefits of using a soft starter with a motor, it can also reduce wear and tear on gear systems and other connected components. Reducing these stresses improves operational performance, decreases maintenance requirements and the associated downtime, and extends the life of the equipment. The controlled acceleration and deceleration of conveyor belts also reduces the risk of load slippage, material damage, spillage during operation, and the sudden jolts that can increase incidents of workplace injuries.

#4 Push-in connectors

Conveyors and other logistics equipment experience a lot of vibration from the constant moving and dropping of packages on the belt. Inevitably, these vibrations will shake loose some of the wiring, leading to unplanned downtime. Additional time and costs can accrue if the technician has to sort through hundreds of wires to find the one causing the issue.

Spring-loaded contact points allow push-in connectors to withstand system vibration during use. Just as importantly, these connection points also stay intact during shipping, even when driven cross-country on the bumpiest of roads. With no loose wires to contend with, implementation is easier and faster, allowing the end user to get systems back online faster.

Build your competitive edge

Components like monitoring relays, machine safety systems, soft starters, and push-in connectors are vital for maintaining uptime in warehousing and logistics. Accelerating response time to potential hazards helps protect both workers and machinery, minimizes the risk of unexpected failures, and keeps maintenance costs in check. As industries evolve and logistics demands intensify, it is increasingly vital for OEMs to deliver forward-thinking machinery that helps their customers achieve key KPIs like increasing uptime and lowering costs. Machine OEMs that can do this most effectively will be best positioned for market leadership in an increasingly competitive landscape.

See related blog post “Don’t run from machine safety. Embrace it!.”

—

Product Marketing Specialist

Matt Darroch

Product Marketing Manager

Product Marketing Manager