Getting inside the humble transformer

Transformers are a foundational component in almost every panel. While it’s a fairly straightforward device, there are probably some things you don’t know about how it works and how you should select your supplier.

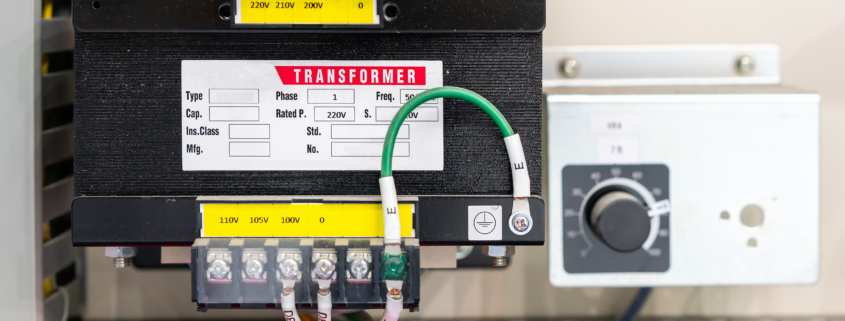

Control panels come in a range of sizes and shapes, and are outfitted with a variety of components. One component you’ll find in almost every panel is the humble transformer. “Humble” because they aren’t particularly sexy compared to other higher-tech panel devices, but they perform several essential functions, one of which may surprise panel builders.

Everyone knows that transformers can step voltage up or down. Most people understand that they do this through induction. In most transformers, an AC voltage is applied to the primary (input) coil or winding, which is wrapped around a metal core. As the voltage oscillates, it creates a magnetic field around the core. This field induces a current in the separate, secondary (output) core winding.

The secondary voltage depends on the turns ratio: the number of windings on the primary compared to the secondary. A transformer with 400 turns on the primary and 100 on the secondary would have a 0.25 turns ratio. Applying 100 volts to the primary would induce 25 volts on the secondary.

Before exploring the role of transformers and looking at some things to consider when selecting the right ones for your panels, let’s look at a brief history of this essential electrical device.

The earliest transformers

The first, widely used transformer was the induction coil, developed in the mid-1800s as a way to get higher voltages from batteries. Since batteries produce direct current, an additional device was needed to create the varying current that’s essential to induction. That device was a set of vibrating electrical contacts called an interrupter that rapidly turns the current on and off.

Transformers were a key player in the “War of the Currents” between Edison (DC) and Westinghouse/Tesla (AC). Because AC voltage doesn’t require an interrupter and was far more efficient than the DC-based induction coil, AC transformers became the keystone of the network of electrical-distribution systems that began to flourish in the late 1800s. Tesla’s 1883 transformers made it possible to generate electric power at low voltages, transform it to higher voltages to reduce losses when transmitted over long distances, and then step it back down to a lower level for end users. This technology breakthrough helped Tesla and Westinghouse win the rights to light the 1893 Chicago World’s fair. The rest, as they say, is history.

Since then, transformers have continued to evolve and diversify in size, shape, and configuration. There are behemoths like the massive 1,100KV distribution transformer – big enough to serve as a bus garage –

to the smallest one, found in electronic devices and measuring about .012” square.

Providing panel power

Transformers used in control panels are at the small end of the size range and almost always used to step power down from 480V or 240V to 120V or 24V. The reason for this stepping down is the main purpose of transformers found in industry: safety. People working around lower voltages are far less likely to be injured or killed by power-related incidents than if they were working with the higher, source voltages.

The lower voltages also reduce the potential for damage to downstream, protected devices and systems by preventing arcing voltages. Many devices, including pumps and motors, draw a lot of amperage as they start up, often as much as 10 times their normal operating amperage. Transformers create a stable secondary voltage during these brief (5-50 millisecond) periods of inrush overload, helping to prevent equipment damage or mis-operation.

Stepping voltage down makes it possible to use smaller, lower-cost components downstream from the transformer. And it enables power supplies to operate with less short-circuit capability.

Selecting panel transformers starts with this simple calculation:

- Determine the supply voltage (incoming power), power frequency, and load voltage of the devices downstream from the transformer – example,

480 V @ 60 Hz. - Calculate the total volt-amperes (VA) by adding the VA drawn during normal operation by all of components (including indicator lights and timing devices) that will be energized simultaneously. Device manufacturers can provide this information.

- From the device manufacturers, add the inrush VA of those components and add it to the VA calculated in step 2.

The calculated inrush includes a good safety factor for the selected transformer. With the totalized inrush and steady state VA amount, use control power transformer manufacturers’ guides and data to determine the proper VA capacity for your application.

Beyond those fundamental transformer parameters, there are a variety of factors or features that panel builders may consider, such as size, weight, heat, mounting arrangement, etc. There are also some opportunities to factor in personal preferences, like terminal blocks versus leads-out configurations.

Selector tools and configurators are available to guide transformer buyers, like the ABB Transformer selection tool.

Minimal product differentiation

While the features and functions of many panel components vary greatly from manufacturer to manufacturer, that’s largely not the case with transformers. Once the panel builder has the basic specs, they can simply turn to their distributor or an online marketplace to find the transformer they need at the best price.

The transformer industry is highly diverse, with suppliers that include OEM components from major manufacturers, relabeled products, and reverse-engineered knockoffs. While there’s certainly some quality difference, it’s not dramatic. That’s why transformer buyers typically rely on brand preference or distributor relationships to guide their transformer-purchase decisions.

Availability is the differentiation

Almost every control panel includes a power transformer. Identifying and purchasing an appropriate transformer is a relatively straight-forward, simple process that comes down to a few application specifications combined with personal preference for some features.

One factor that often differentiates transformer suppliers is product availability. While panel builders typically won’t have trouble finding a transformer that will do the job, preferred suppliers will have the best product selection and availability to provide a transformer that will best fit the precise panel requirements.

—

Frank Basciano Global Product Manager,

Smart Buildings, LV Dry Type Transformers & SPD

Chris Kniedler

Product Marketing Manager – US NEMA Commercial Products

Patti Hussey

Product Marketing Manager – LV Dry Type Transformers

ABB Electrification Business