What you need to know about miniature circuit breaker trip curves

One of the critical criteria when selecting miniature circuit breakers is their trip curve. Awareness of these curves will help you select the right breakers for your applications, and diagnose potential nuisance tripping issues.

Trip curve basics

Electrical protection devices, with virtually no exceptions, operate based on a simple formula: If THIS, then THIS. If this limit reaches a certain level, then the device executes the designed or programmed action. Today’s large, molded-case circuit breakers may include algorithms consisting of a complex set of If/Then parameters. Miniature circuit breakers (MCBs), on the other hand, operate based on only two parameters: overload and short-circuit.

Still, even with these two basic parameters, breaker buyers face a broad selection of miniature circuit breakers that could potentially meet their application requirements. Selecting the optimum miniature circuit breaker is critical to helping ensure proper protection, with minimal or no nuisance tripping, at the lowest possible cost. Making the right selection requires an understanding of the basics of trip curves.

Understanding trip curves

Most protective devices have a defined trip curve, also referred to as a time/current curve, that describes the behavior of the device. The curve is literally a graphic representation of how the device will respond to changes in current. From a functional perspective, the curve parameters specify the high and low current thresholds that will cause the device to trip.

Selecting the appropriate trip curve achieves a good balance between overcurrent protection and optimal machine operation. A fast-acting trip curve will do an excellent job of circuit and production equipment/load protection, but at the cost of frequent and costly nuisance tripping (mostly due to inrush currents of motors and transformers). Choosing a breaker with higher trip points or thresholds will better keep the process up and running, but might cause more temperature rise in cables/conductors and connected loads.

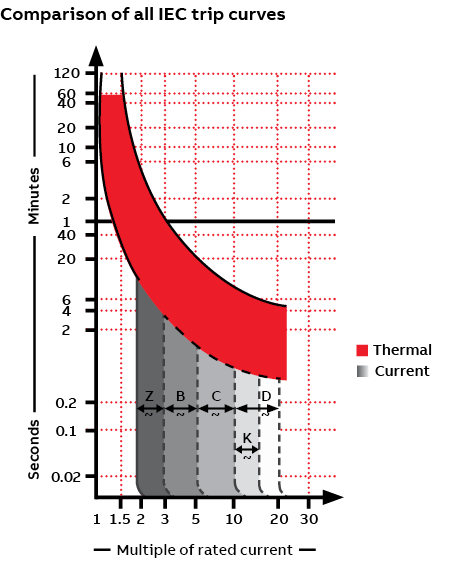

Trip curves are defined by IEC standards 60898-1 and 60947-2. The curves actually represent two different trip functions within the miniature circuit breaker – thermal and electro-magnetic. The thermal section (top section of the chart) that responds to overloads typically consists of a bi-metallic strip. The response of the thermal trip unit is relatively slow. The thermal section, which also complies with UL standards in addition to the before-mentioned IEC standards, is similar across all trip curves.

The short-circuit section (bottom) relies on a magnetic coil or solenoid that opens if the overcurrent design limit is reached. This section of the breaker responds within milliseconds. This characteristic of the trip curve has no counterpart on the UL side.

Trip curve origins

The concept of trip curves originated in the IEC world. The alphabetic code used to categorize miniature circuit breakers (B, C, D, K, and Z) carried over from IEC standards. The standard defines the lower and upper thresholds for tripping, but manufacturers have the flexibility to decide the precise specifications within those thresholds that will cause a trip in their products. The trip curve graph shows the tolerance band within which manufacturers can set the individual tripping point of their breakers.

The characteristics and applications of each curve, from most- to least-sensitive are:

Z: Trips at 2 to 3 times rated current. Suitable for highly sensitive applications, e.g., semiconductor devices.

B: Trips at 3 to 5 times rated current.

C: Trips at 5 to 10 times rated current. Suitable for medium inrush currents.

K: Trips at 10 to 14 times rated current. Suitable for loads with high inrush currents, mostly for use with motors and transformers.

D: Trips at 10 to 20 times rated current. Suitable for high starting currents.

Referring back to the “Comparison of all IEC trip curves” graph, you can see that higher currents trigger more rapid trips.

The ability to tolerate inrush current is an important consideration in trip-curve selection. Certain loads, notably motors and transformers, experience a momentary change in current, the inrush current, at contact closure. Faster protective devices, like a B-trip curve, would see this inrush as a fault and open the circuit. For these types of loads, trip curves with a higher magnetic tripping point, either D or K, can “ride through” the momentary inrush of current, protecting the circuit without nuisance tripping.

Choosing the right trip curve

The availability of a range of trip curves and options for different current levels within each range enables selection of an appropriate breaker to protect a variety of loads in various applications.

With large, molded case circuit breakers, you can select one of a number of breakers and then adapt it to the application by adjusting its operating parameters. The same isn’t true for miniature circuit breakers. Their operating parameters are fixed, making it critical that you select the breaker to meet the required specs, including the appropriate trip curve for the application.

Armed with the operating values for a circuit or application/load, it’s possible to make a good selection of the appropriate trip curve. However, this may require some trial and error to arrive at the optimum breaker. Recurring nuisance tripping may be a sign an alternate may be a better fit.

To help ensure the optimal balance between protection and minimal nuisance tripping, the best approach may be to consult with the device manufacturer or distributor. Provide them with the details of your application, and they should be able to recommend the right miniature circuit breakers to meet your needs.

—

Thomas Weinmann

Senior Product Marketing Manager