Higher solar voltage / New panel opportunities

Solar-PV energy providers no longer need complex solutions to match 800/1000 VAC array outputs to lower-voltage storage systems. Panel builders can support their shift to much simpler, more efficient, more reliable 800/1000 VAC storage.

You’ve probably seen a YouTube video or Facebook post showing some preposterously large engine jammed into a too-small car, boat, or lawn tractor. These mismatches are fun to see but clearly took a considerable amount of time to assemble, are expensive to build, and no doubt require near-constant maintenance to keep them operating. They’re for fun, not function.

A serious mismatch of components is also frequently found in solar photovoltaic (PV) farms, with some of the same resulting problems. Of course, this mismatch wasn’t created for entertainment or fun. It was necessary due to the imbalance between the 1500 VDC solar PV array output voltages and the lower operating DC voltages of the battery energy storage systems (BESS) storing the energy.

The traditional solution was to add a voltage divider to the output of the PV array feeding into the batteries for charging or combining batteries in parallel to match the 1500 VDC from the PV array. That meant adding additional components such as a miniature circuit breaker and other components to connect, protect and isolate the battery banks. These components added capital costs, maintenance time, energy loss, and created additional points of failure.

Today, more panel and combiner-box builders are equipping or retrofitting solar farms with the now-available 1500 VDC BESS. The voltage-for-voltage match greatly simplifies the system, with many benefits.

Evolution of solar PV

The evolution of high-efficiency PV string inverters is driving a shift toward higher AC voltages in utility-scale solar applications. Using string inverters in solar plants rated at 20 megawatts and below can be extremely beneficial. With output voltages now as high as 1000 VAC, the same amperages will yield higher-output power levels.

Solar PV string inverters were initially used primarily in residential and commercial building applications up to 1 MW in size. This was limited to traditional AC voltages of 120 VAC single phase and 480 VAC three phase. String inverters are well suited to rooftop solar applications due to their relatively small size and ease of installation for inverters rated 100 KW and below. So, string inverters can easily be connected to standard building cabling and existing rated wiring.

Benefits of going to higher voltages

A typical string inverter rated 100 KW at 480 VAC will yield approximately 208 amps. New string inverters rated 100 KW at 1000 VAC will yield approximately 100 amps. This reduction in amperage reduces heat in cabling and reduces the required diameter of the wire, resulting in cost savings. Cable connectors can also be smaller, helping to make wiring and connection easier.

Because string inverters are much smaller and lighter than large 1 MW+ central inverter skids, no heavy equipment is needed for installation. This is especially important in locations that cannot be accessed by the tractor trailers and cranes needed to install central inverter skids. By contrast, string inverters can be transported to sites using standard utility trucks. Installations are normally performed by two technicians and can be mounted directly to the PV array structure.

Using string inverters also allows for increased monitoring at the PV array level.

Challenges of higher voltages

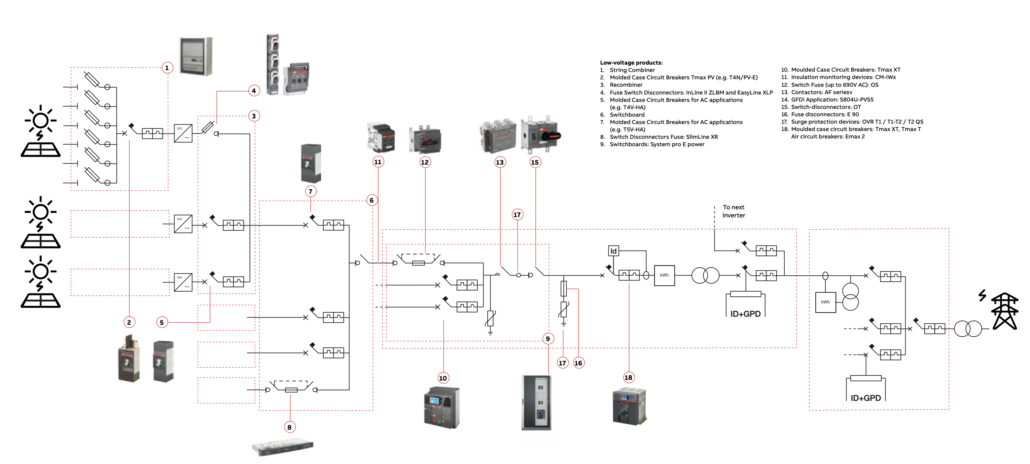

The line diagram in figure 1 above shows that outputs from string inverters are summed together in an AC panel board (also known as an AC combiner or re-combiner) in a typical string inverter application at utility scale. In this case, all the connection components will have to be rated at or above the output voltage and current of the string inverters. In addition, the protection components such as breakers must have a high enough kiloamp interrupting capacity (KAIC) rating in order to protect the system from a short circuit condition downstream.

The AC combiner is normally connected to a step-up transformer rated 34.5 KVA on the secondary side, which implies a breaker rating of 35-45 KAIC. Higher string-inverter output voltages require higher-KAIC rated components in the AC combiner box.

In Europe, IEC-rated products are prevalent, and there are several components that have the IEC-required KAIC ratings at 1000 VAC and 800 VAC. By contrast, in the US today there are only a few UL-rated components on the market at the 1000 VAC level. Several are available at 800 VAC and more at 600 VAC.

Components available to AC panel board and AC combiner OEMs working with UL system include:

Disconnect switches – For isolation and maintenance; 600-1000v fused and non-fused up to 800a

Molded case circuit breakers – For protection, isolation, and monitoring input from string inverters; 600-800v, 250a to 400a up to 35 KAIC

Air Circuit Breakers – For main circuit protection and monitoring after inverter inputs are paralleled; 600v, 3,200a at 40 KAIC and 800/900v, 3,200a at 40 KAIC (IEC only)

Surge protective devices – To help divert the lightning currents within an electrical system resulting from indirect lightning events

Contactors – For remote switching; 600v, 25a to 1350a and 1000v, 60a to 1650a

AC-panel and combiner-box builders can rest assured they are integrating the correct, state-of-the-art components to meet the needs of their customers who choose to use solar PV string inverters for their utility-scale solar PV plants.

In addition to the higher-voltage levels, PV systems are also being fully integrated with cloud-based measuring and monitoring tools. Including components that support this level of functionality (e.g., the ABB AbilityTM platform) as part of system design will help ensure better efficiency and durability.

Summary

PV-farm builders and operators constantly look for ways to maximize the efficiency and profitability of their assets. Panel builders can respond to this need with technology supporting the shift toward 1500 VDC BESS that are matched to the array output.

Matching array output with BESS input voltages means fewer components with lower losses and simpler, more reliable systems that require less space. Many of the components operating at these higher voltages are also more efficient than their lower- voltage alternatives, further increasing farm profitability.

Fewer components also means fewer shipments. In this day of supply chain issues, a simpler order likely means less chance or delivery delays and frustrations.

In solar PV, as in most systems, simpler is far, far better. Creating that simplicity represents a great opportunity for panel builders.

_

Allen Austin

Sr. Renewable Energy Market Development Manager